-

Metal roofing sheet forming machine

-

Metal Floor decking forming machine

-

Automatic C/Z purlin forming machine

-

Stud and track forming machine

-

Sandwich panel forming line

-

Roller shutter door forming machine

-

Highway guardrail forming machine

-

Slitting line, cut to length line

-

CNC bending/shearing machine

-

Accessories

-

Rain gutter and downpipe machine

-

Punching and shearing machine

1. Technical parameter and accessories

Parameter | Specification | |

1 | Processing material | Strip steel / galvanized steel coil / GI / PPGI. |

2 | Certification | CE / BV / ISO / SGS |

3 | Voltage | AC 380V 50-60Hz 3Phases or as per your request. |

4 | Power | 5.5kw main motor with 350PM reduction |

5 | Processing thickness | 0.3-0.6mm |

6 | Feeding width | According to your profile drawings. |

7 | Output width | According to your profile drawings. |

8 | Diameter of shaft | Φ50mm (Solid shafts) |

9 | Roller stations | 12 stations |

10 | Machine size | About 6.0*1.0m * 1.25m |

11 | Productivity | Non stop cutting 35-40 m/min |

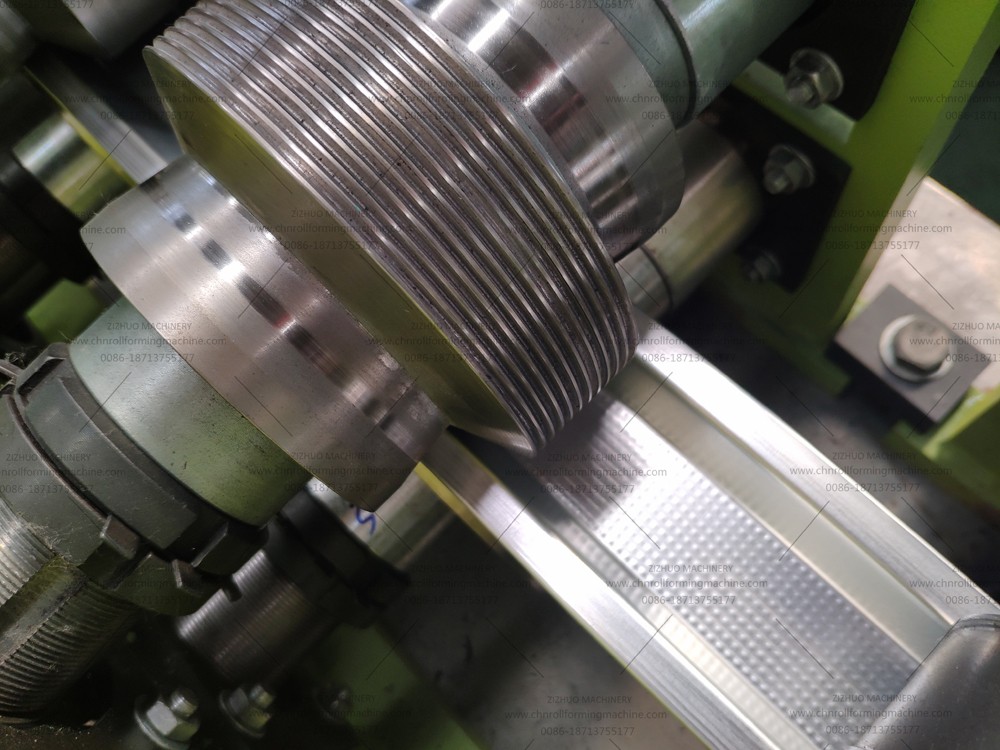

12 | Roller material | Cr12 mould steel with quenched treatment |

13 | Cutter material | Cr12 mould steel with quenched treatment |

14 | Screw | Galvanized national standard |

15 | Control system | Delta PLC (made in |

16 | Drive method | 1’’ Chain transmission |

17 | Electron component | Schneider |

18 | Encoder | Omron |