-

Metal roofing sheet forming machine

-

Metal Floor decking forming machine

-

Automatic C/Z purlin forming machine

-

Stud and track forming machine

-

Sandwich panel forming line

-

Roller shutter door forming machine

-

Highway guardrail forming machine

-

Slitting line, cut to length line

-

CNC bending/shearing machine

-

Accessories

-

Rain gutter and downpipe machine

-

Punching and shearing machine

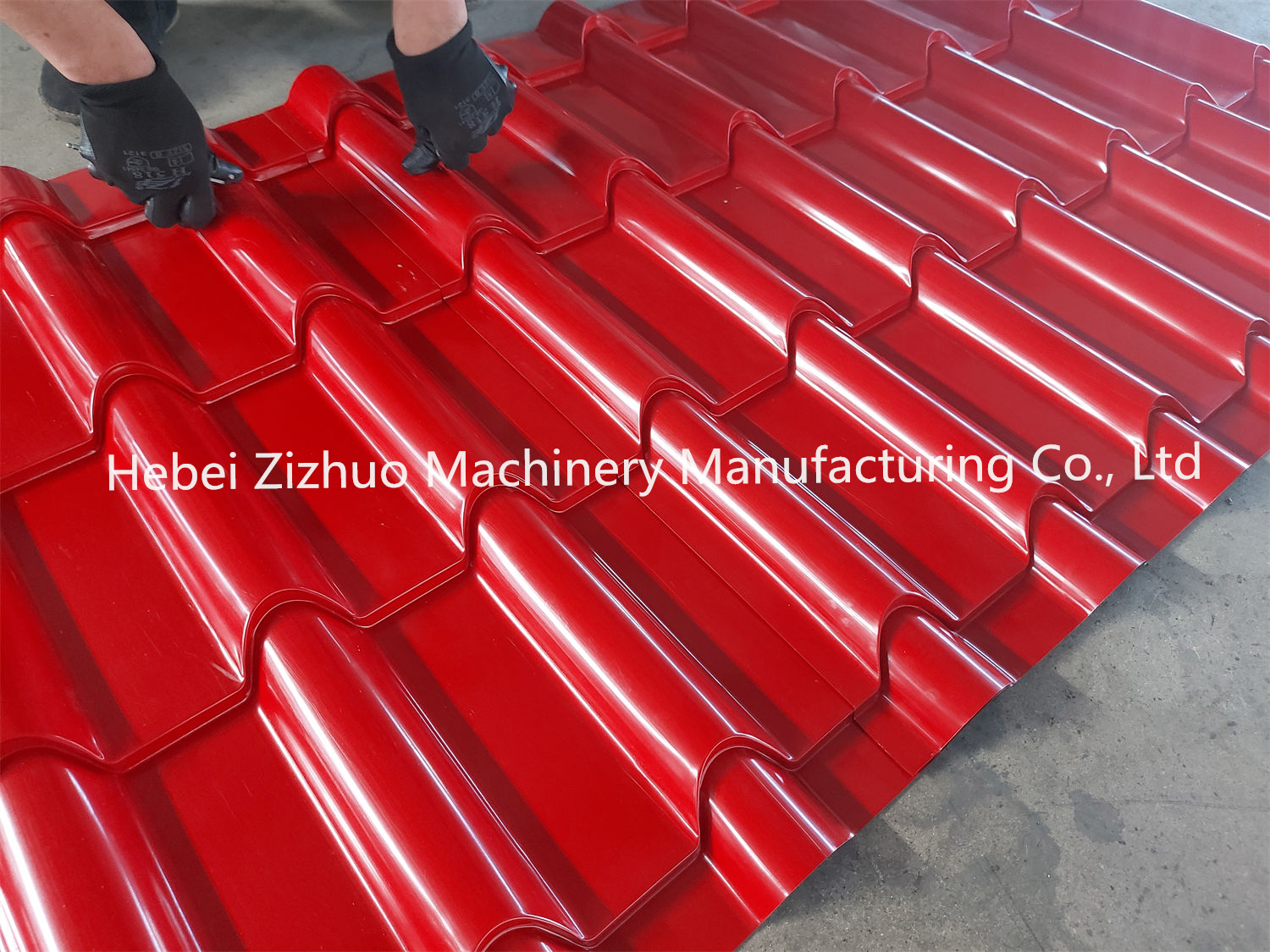

Colombia double layer Mectoppo Roof tile and Trapezoidal Sheet Roll Forming Machine

Technical parameters:

No. | Item | Parameter | Remark | |

1 | Suitable material | Type | Color steel, galvanized steel | |

Thickness(mm) | 0.3-0.6mm | Test material standard 0.5mm | ||

Yield strength (Mpa) | ≤300mm | |||

Width (mm) | About 1219mm | |||

2 | Forming speed | Roofing sheet 12-15 m/min | Not include cutting time | |

3 | Motor of forming system (kw) | 7.5kw | ||

4 | Hydraulic station power(kw) | 4kw | ||

5 | Voltage requirements | AC380V, 60Hz, 3phase | According to customer’s request | |

6 | Shafts | 70mm | Solid bearing steel | |

7 | Roller station | Tile13 steps PIT900 15 steps | ||

Roller material | #45 steel | 58-62 degree heat treatment | ||

8 | PLC control system | Delta | Touch screen | |

9 | Transducer | Delta | ||

10 | Machine dimension | 8.2*1.6*1.75m | ||

11 | Weight | About 6.5 ton | ||

12 | Transmission | Chain | 1.0’’ | |

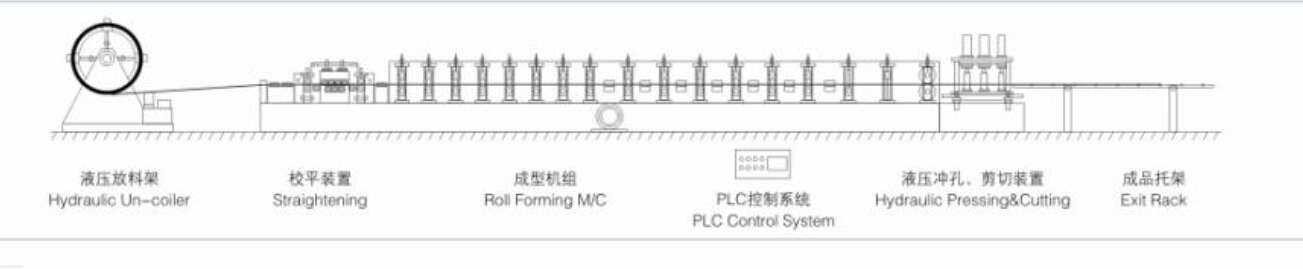

Process Flow Chart

Decoiler --- guiding system --- roll forming --- cut to length --- product to supporting table